Born 50 years ago to prevent "what ifs" from happening

Hardlock nut.

The next 50 years will be about making "what if" a reality.High strength composite plastic screws

We will continue to challenge ourselves to develop the following :

HARDLOCK Industry will act as a wedge between

Japan's traditional techniques and

next-generation cutting-edge technology to bring them together

and take on new challenges.

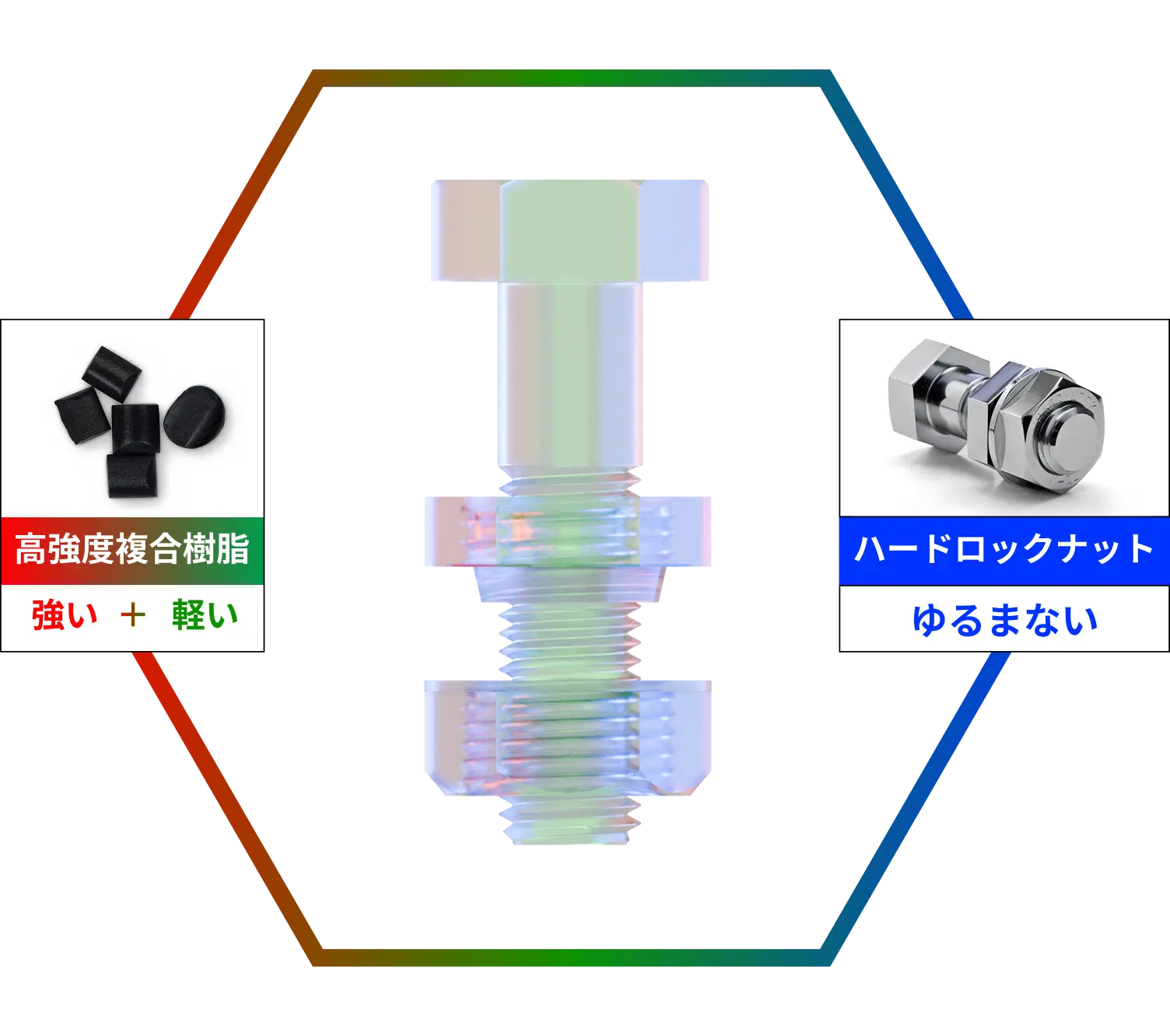

HARDLOCK Industry will use the various technologies available in the world as a wedge for integrated development. One of the products that we are trying to create from this new challenge is a high-strength composite plastic screw.

This is being promoted with the support of the Ministry of Economy, Trade and Industry's Research and Development Support Project for Growth-oriented Small and Medium-sized Enterprises, etc., JPJ005698, fiscal year 2023.

Masahiko Wakabayashi, President and CEO, Hardlock Industry Co., Ltd.

High Strength Composite Plastic Screw

What are high-strength composite plastic screws?

Conventional plastic screws have lower strength than metal screws. On the other hand, plastic screws have the advantage that they can be made lighter.

We have focused our research on the idea that if we can create a "light and strong" plastic screw, we can create a new future.

This high-strength composite plastic screw also incorporates our valued "wedge integration technology." Although there are still challenges to overcome before it can be commercialized, we will continue to take on these challenges together with you.

Three Points of the High Strength

Composite Plastic Screw

Three points about high-strength composite plastic screws

Target User

Intended use

Our previous products had the problem that their use in aircraft was limited due to the characteristics of the product using two nuts.

The applications of high-strength composite plastic screws, which are one-fifth the weight of conventional metal screws, are endless.

They are particularly suitable for use in places where weight reduction of parts is essential and where loosening due to vibration is likely to occur.

In the future, we aim to adopt them in drones and flying cars.

Structure And Features

Structure and Features

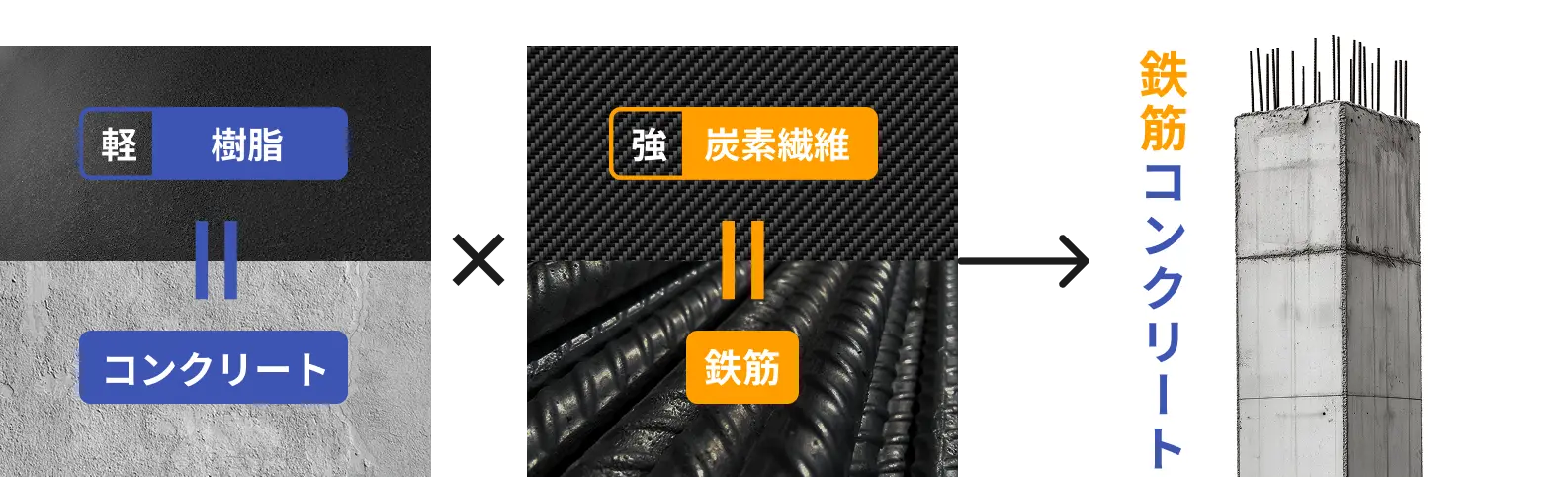

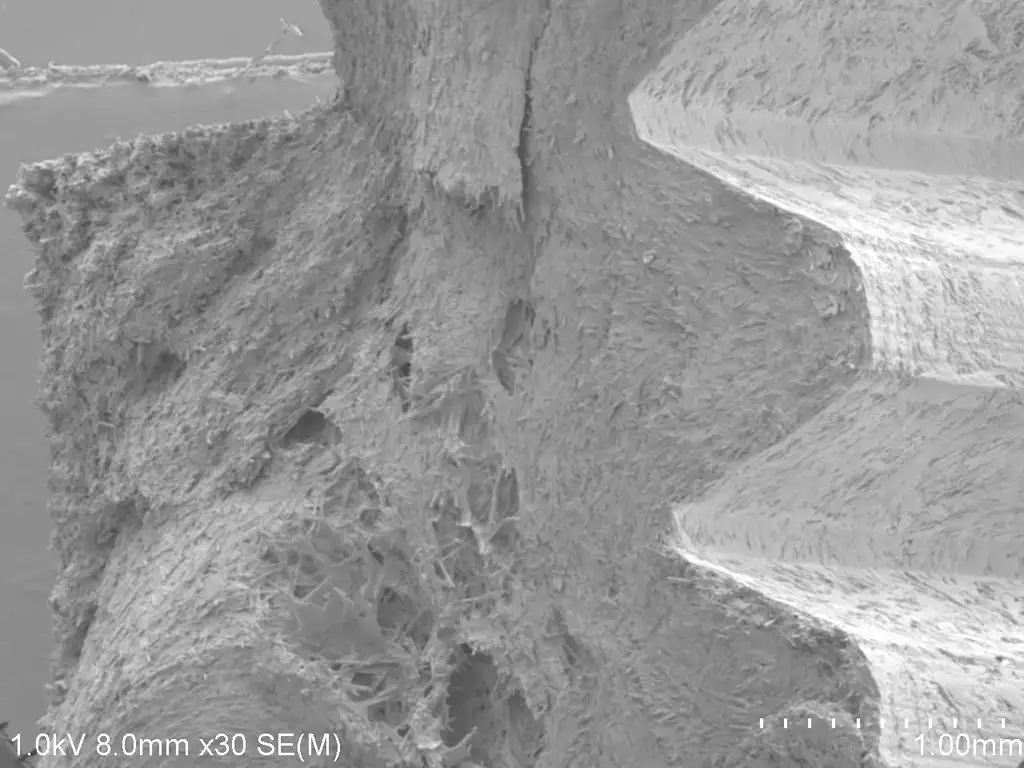

The high-strength composite plastic screw currently under development utilizes the mechanism of reinforced concrete and has a structure that is both light and strong. By combining carbon fiber (reinforced concrete), which is strong against outward pulling forces, and resin (concrete), which is strong against inward pushing forces, we aim to create a plastic screw with the same strength as metal.

Method of High Strength

The secret of strength

The high-strength plastic screw we are developing has a target strength equal to or greater than that of aluminum alloy (A5052), with a tensile strength of 350N/mm2 (30kN for M12 size) or greater.

Aluminum alloy is the most versatile material and is also used for screw parts.

This is a plastic screw product of the near future that combines thermoplastic resin, which is difficult to increase in strength, with reinforced fiber using new technology.

Composite Of Resin And Carbon Fiber

Combination of resin and carbon fiber

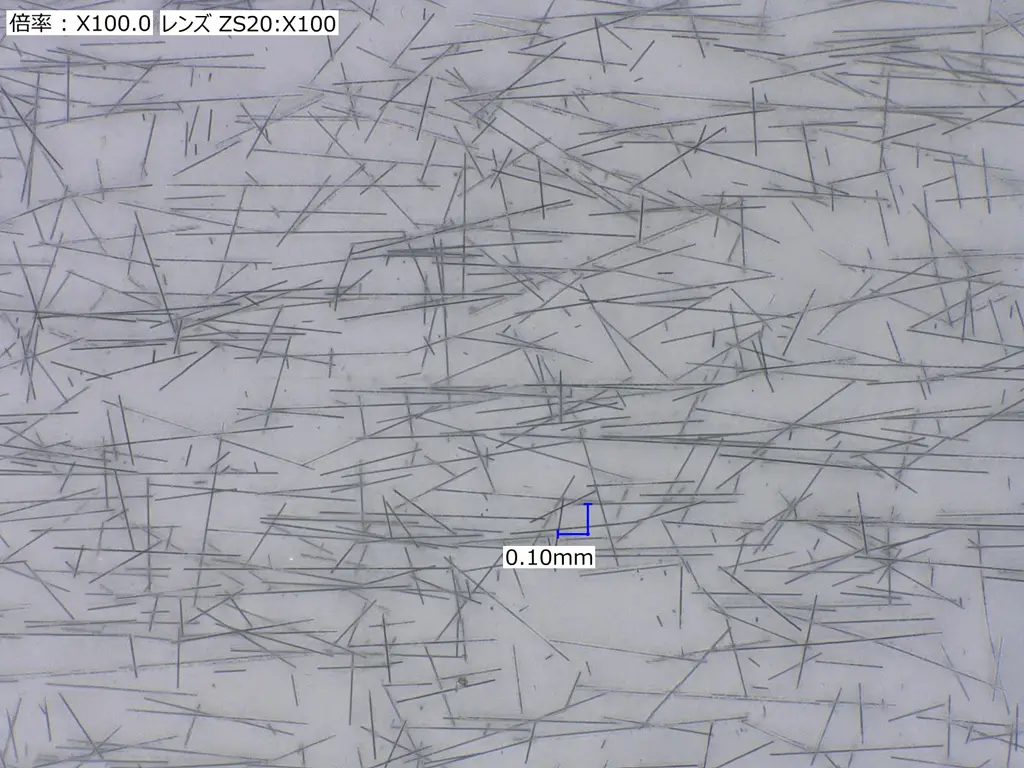

The strength is increased by dispersing the carbon fibers in the resin in various directions.

Enhanced Adhesion

Enhanced adhesion

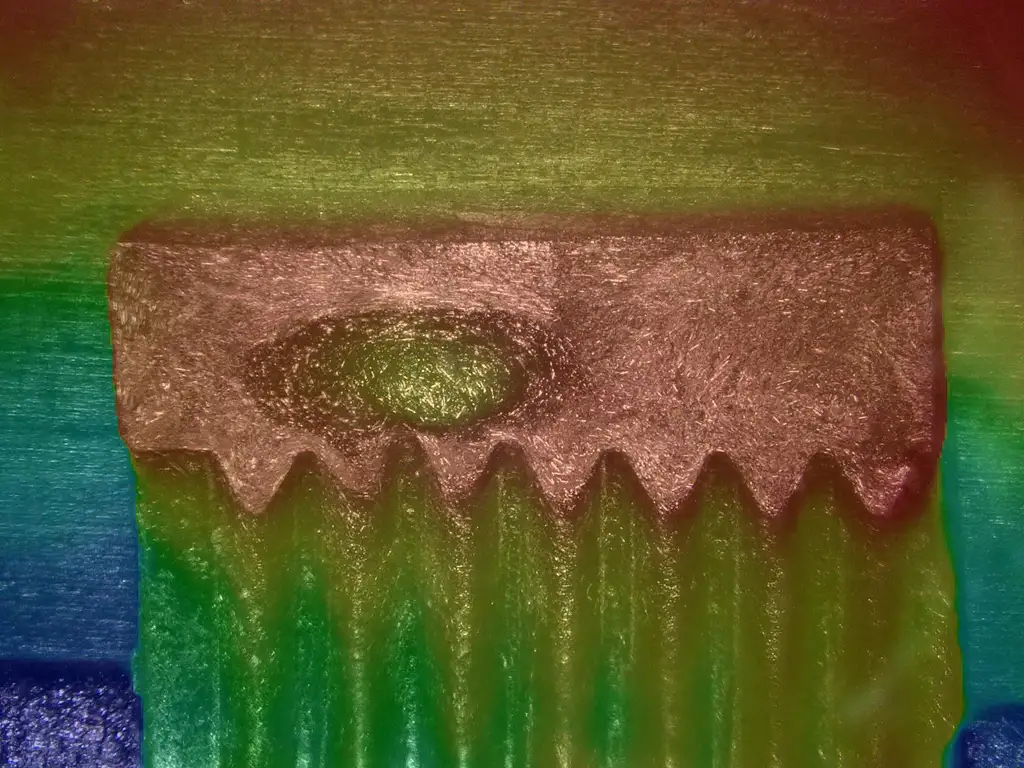

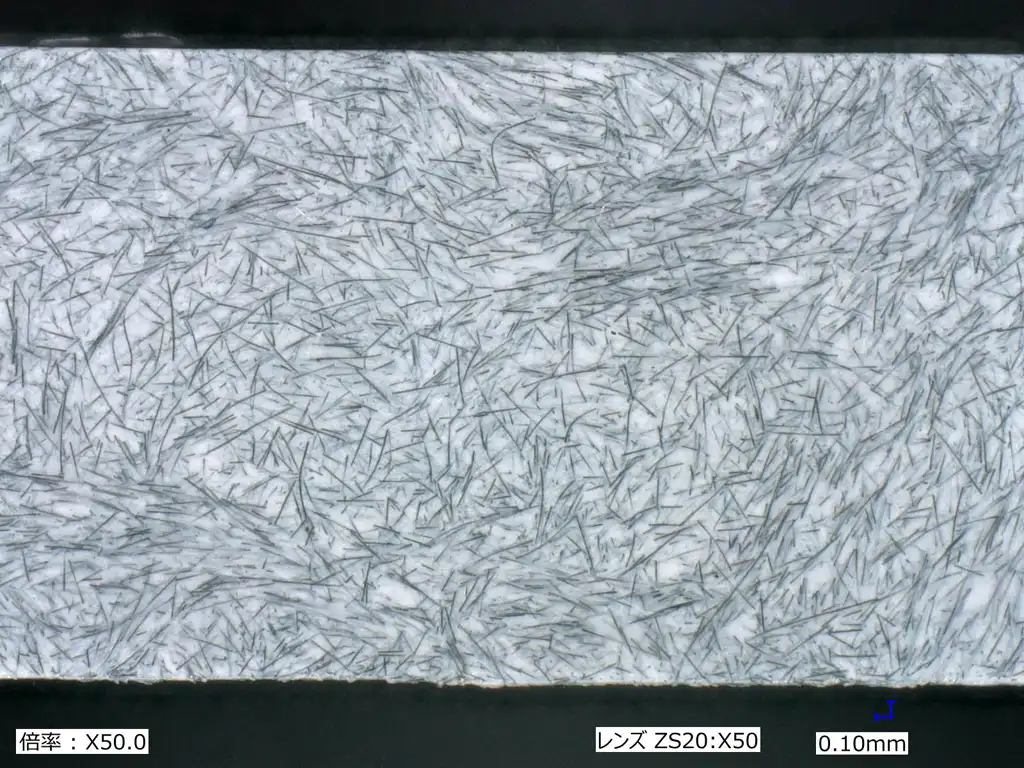

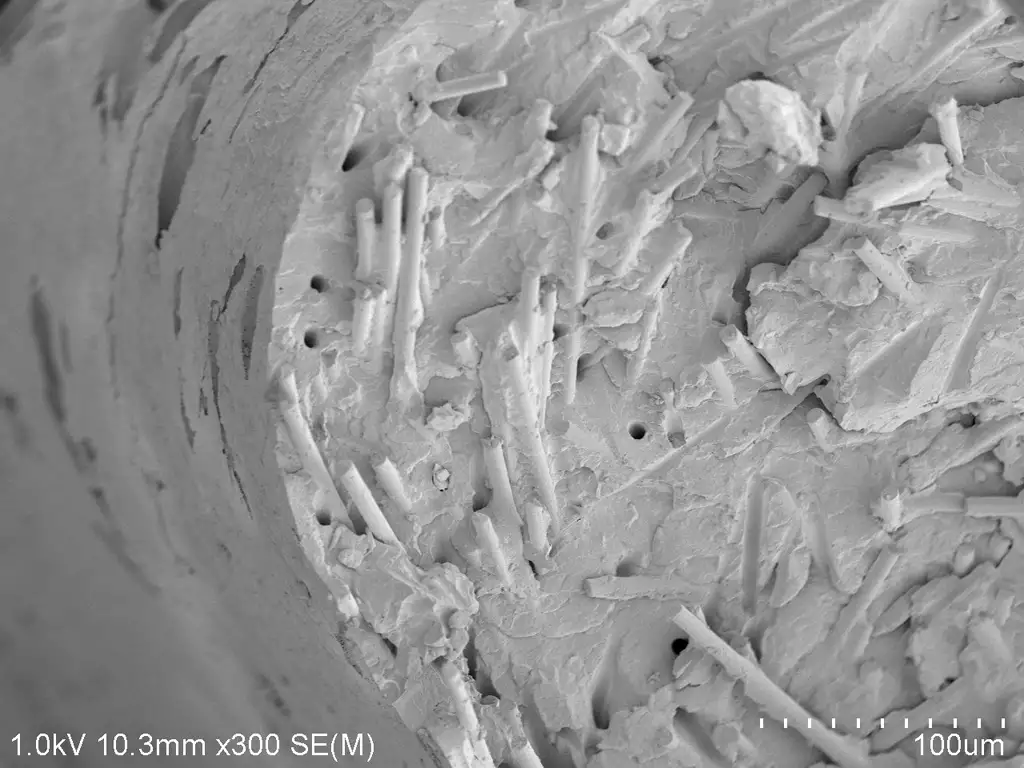

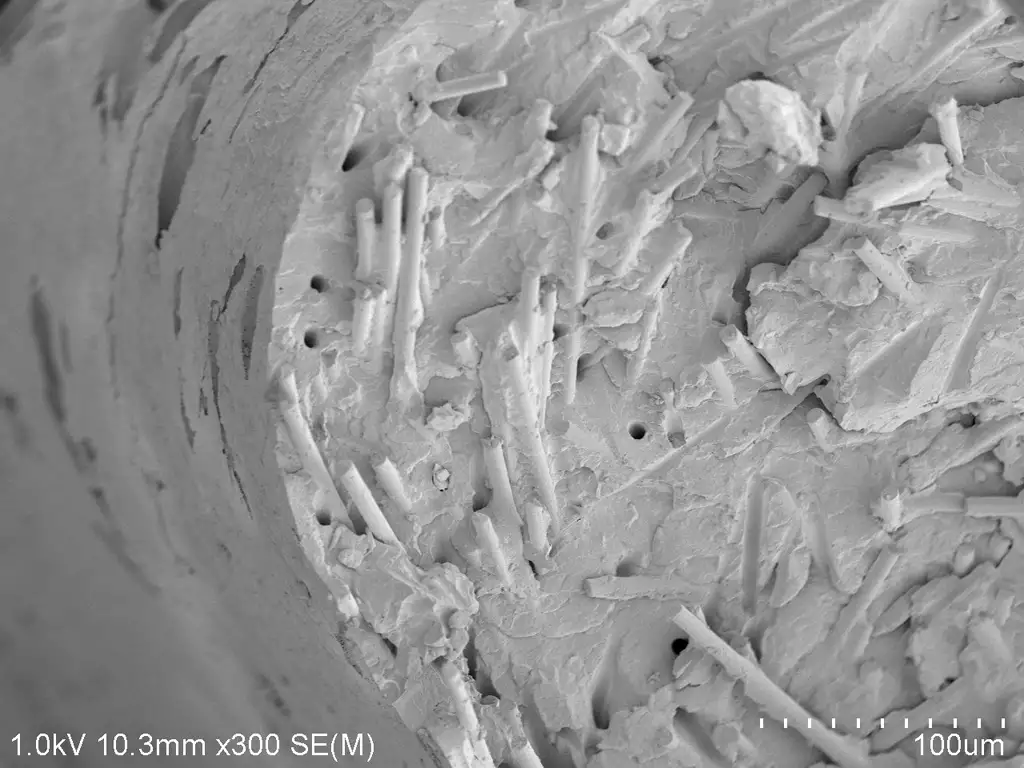

If the adhesion between the resin and carbon fiber is poor, the carbon fiber will come out, creating holes and reducing strength.

We are researching technology that makes it difficult for the carbon fiber to come out, making the product stronger.

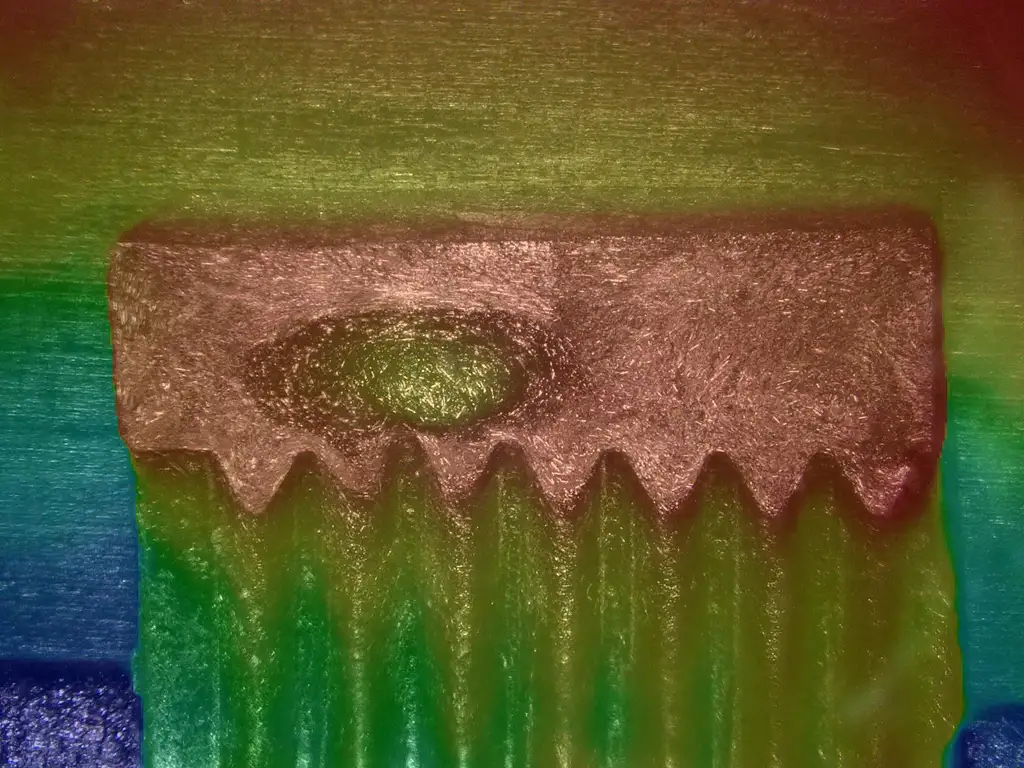

Prevent of Void

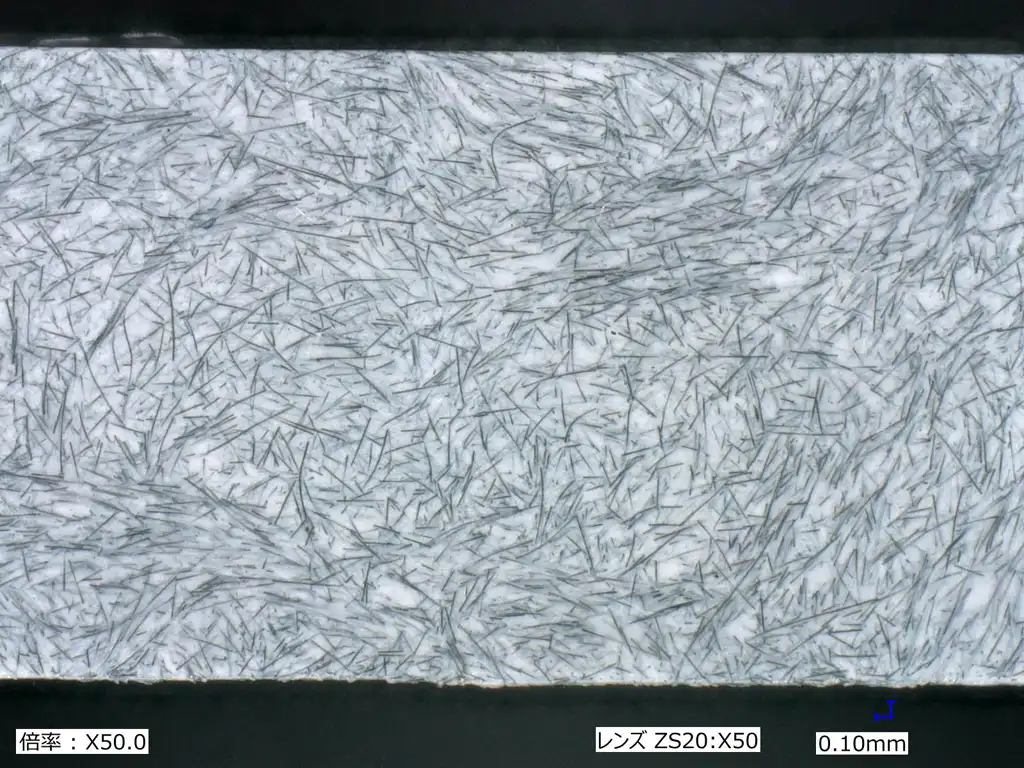

Preventing voids from occurring

Air bubbles called voids that form in molded products reduce their strength. To prevent voids from occurring, molding is done by controlling the optimum temperature and pressure.